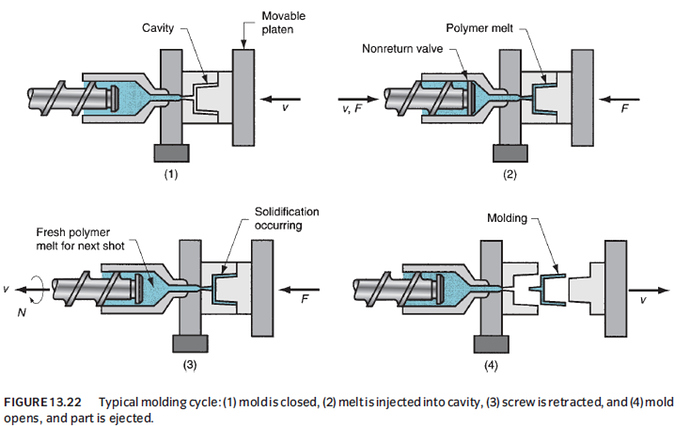

Injection Molding is the most widely used molding process for thermoplastics in which a polymer is heated to highly plastic state, forced to flow under high pressure into a mold cavity, and ejected after solidification.

Applications:

- Complex, intricate shapes.

- Ideal for high-volume production runs due to high cost of tooling ($$$$) for designing the mold cavity

Process:

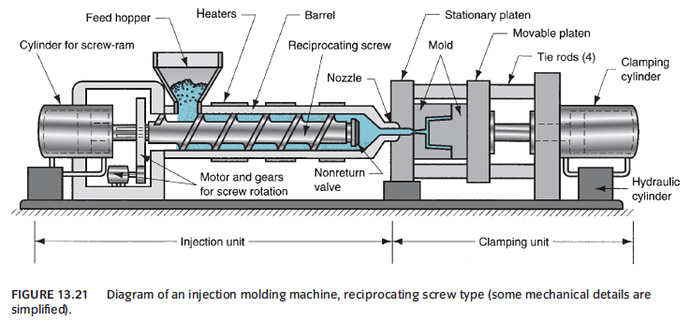

- Two main components: Plastic Injection Unit and Mold Clamping Unit

- Injection unit contains barrel that is fed from hopper containing plastic pellets

- Reciprocating screw mixes and heats the polymer while also acting as ram to inject molten plastic into the mold. Non-return valve prevents flow from flowing backward