Extrusion is a compression process in which material is forced to flow through die orifice to provide long continuous product.

Applications:

- Tubing, pipes, hose, sheets, cabling

- Any type of long parts with solid or hollow cross-sections

Process:

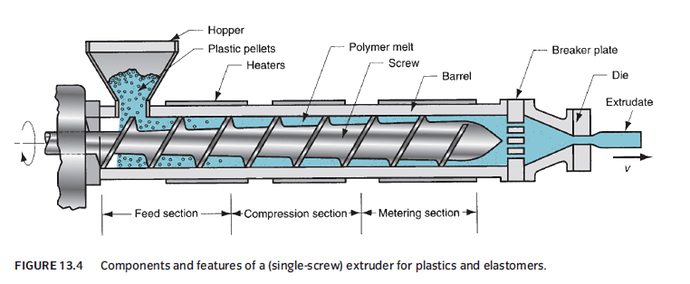

- In polymer extrusion, feedstock in pellet or powder form is fed into an extrusion barrel where it is heated and melted and forced to flow through a die opening by means of a rotating screw. The two main components of the extruder are the barrel and the screw. The die is not a component of the extruder; it is a special tool that must be fabricated for the particular profile to be produced.

- The cross-section is determined by the shape of the orifice.

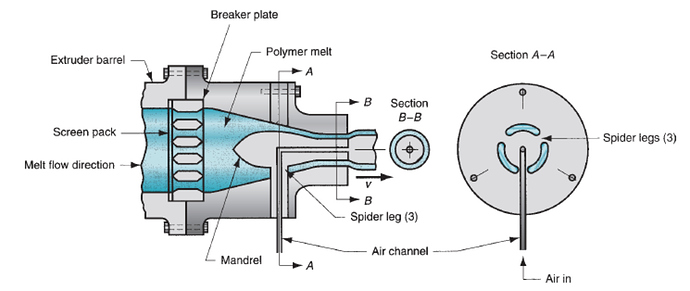

- Hollow Profiles: Requires a mandrel to form hollow shape; often contains air channel where air is blown to maintain hollow form during hardening