Three Major Types of Sheet-Metal Processes:

- Cutting

a. Shearing: Cutting operation along a straight line between two cutting edges

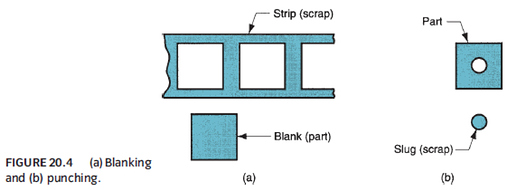

b. Blanking: Cutting operation along closed outline in single step to produce desired part

c. Punching: Cutting operation along closed outline where remaining stock is the part

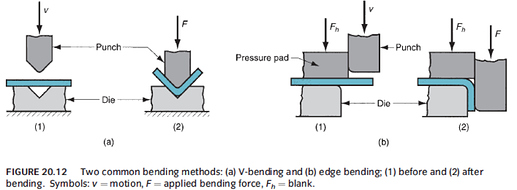

- Bending: Straining of metal around a straight axis to produce plastic deformation

a. Produces little or no change in thickness of sheet metal

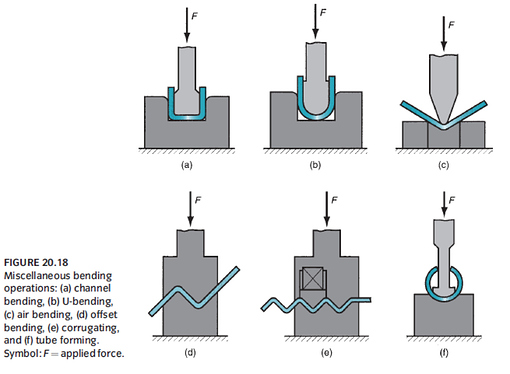

Other Bending/Forming Operations

- Flanging: Straight, stretch, shrink

- Hemming: Bending the edge of the sheet over on itself in more than one bending step

o Improves stiffness and improves appearance - Seaming: Similar to hemming but where two sheet-metal edges are assembled

- Curling: Forms the edges of the part into a roll or curl

o Done for safety, strength, and aesthetics

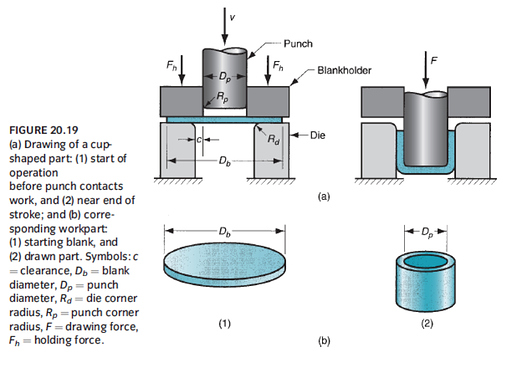

- Drawing: Sheet-metal forming process used to make cup-shaped, box-shaped, or other complex-curved and concave parts

a. Common parts: beverage cans, ammunition shells, sinks, cooking pots, automobile body panels

- If shape change required by the part design is too severe, complete forming of part may require more than one drawing step

o Additional steps called redrawing - Blank holder purpose: Prevents wrinkling of the flange while cup is drawn

o Wrinkling, tearing, earing, surface scratches