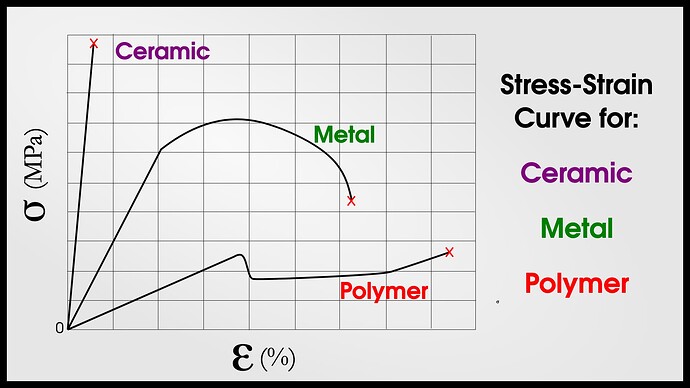

A general stress-strain curve for metals, polymers (i.e. plastics), and ceramics is shown below:

Ceramics are typically the strongest (Young’s Modulus), polymers have the greatest elongation (% strain = Change in Length/Original Length), and metals are often the toughest.

Let’s look at some important mechanical properties for each material:

Aluminum 6061

- Yield Strength: 69 MPa

- Ultimate Tensile Strength: 130 MPa

304 Stainless Steel

- Yield Strength: 200 MPa

- Ultimate Tensile Strength: 580 MPa

Delrin (Sample Representative Plastic)

Values above are referenced this database of material properties, Make It From and MatWeb. For hardened steel, let’s assume we have some x MPa increase in both yield & tensile strength.

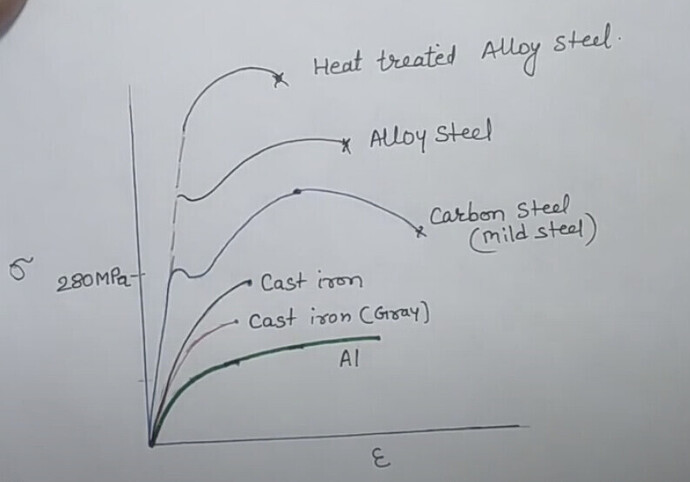

As such, we can see that the stress-strain curve would look similar to this for aluminum and different grades of steel: