Describe how you approach material selection/design for a component where strength is critical, and how you would approach a different component where stiffness is critical?

When dealing with material selection, it’s often easy to confuse the difference between strength and stiffness. With metals for example, isn’t strong metal stiff and stiff metal strong? ![]()

Quite the tongue twister, but let’s break it down in simpler terms.

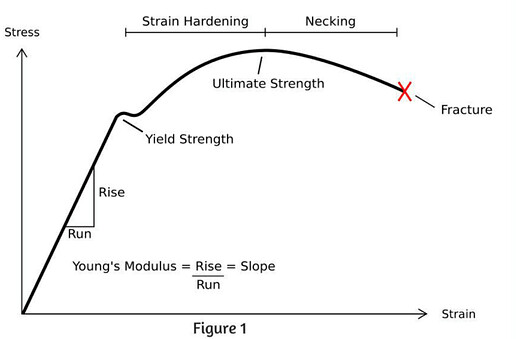

Strength: Measures how much stress can be applied before material deforms permanently/fractures

Stiffness: Measures the resistance to elastic deformation (i.e. non-permanent deformation, will return to original shape)

The Young’s Modulus measures the stiffness in a material, and strength is a function of the modulus. Objects with a high stiffness will resist changes in shape when being acted on by a physical force.

Imagine a metal bar and rubber-like polymer bar loaded under tension and pulled until the specimen fractures.

Metal Bar: Fractures at 100 lbf, deforms 1% of original length

Rubber-Like Bar: Fractures at 100 lbf, deforms 10% of original length

Both materials here are equally strong, but the metal is much stiffer than the rubber polymer. Here, the metal deflects less for the same loading conditions.

Rubber Polymer = High strength, low stiffness

Metal Bar = High strength, high stiffness

For structural parts, it’s very typical that the application will require both high stiffness + strength, the two terms however refer to different properties of a given material.

References: