Slides and lifters are mechanisms used to create complex geometries and allow for the release of undercuts or other features that would otherwise make part ejection difficult.

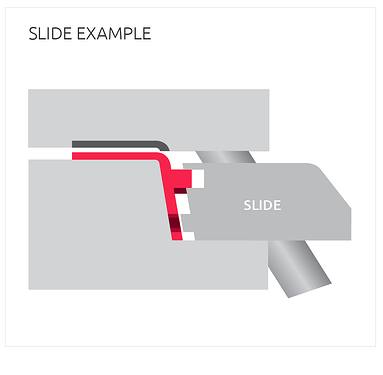

Slide

- A slide (also known as a side-action) is a component of the mold that moves perpendicular to the opening direction of the mold. It is used to form undercuts or side details on the molded part.

- Function: Slides are moved into position during mold closing and retracted during mold opening. This movement is often driven by cam pins or hydraulic cylinders

- Uses: Slides are typically used for features such as holes, slots, or recesses that are perpendicular to the mold’s parting line.

- Example: If you need to mold a part with a hole that goes through the side of the part, a slide would be used to form this hole.

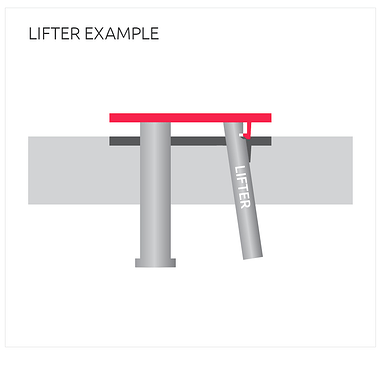

Lifter

- A lifter is a component that moves in an angled or straight path to release undercuts and internal features. Lifters move with the opening direction of the mold but also have an additional motion to clear the undercut.

- Function: Lifters move out of the way as the mold opens, allowing the molded part to be ejected without damaging the undercuts. This movement can be achieved through mechanical linkages or hydraulic actuation.

- Uses: Lifters are typically used for features such as internal hooks, snaps, or other undercuts that are difficult to release with simple straight ejection.

- Example: If you need to mold a part with an internal snap fit feature, a lifter would be used to form the snap fit and then retract to allow part ejection.

Comparison

- Direction of Movement: Slides move perpendicular to the mold opening direction, while lifters move in line with or at an angle to the mold opening direction.

- Complexity: Slides generally require more complex mechanisms and precise control due to their perpendicular movement. Lifters can be simpler but must be carefully designed to avoid part damage during ejection.

- Applications: Slides are more suited for side features and external undercuts, whereas lifters are better for internal undercuts and features that are integral to the part’s design.