Hint: What are things to consider when designing snap fits (i.e. strain vs. deflection, number of uses)?

Backpack buckles are a classic example of snap fits! It’s important to note this is not as simple as making the buckle more stiff. Snap fits are a more nuanced design, where you have to balance deflection and strain.

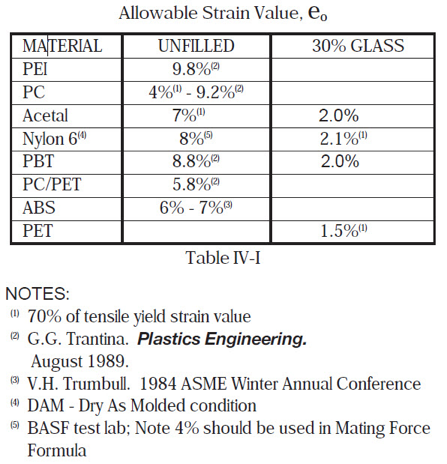

To make sure your buckle doesn’t break, during design you have to ensure that the buckle during use is within the allowable strain and permissible deflection limits. As such, during design of the part you will compare your design’s max deflection/strain and compare against reference values for allowable strain and deflection.

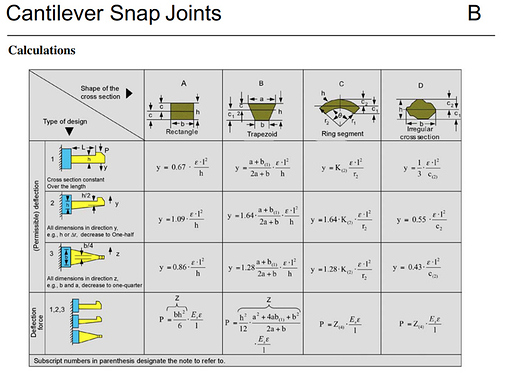

The table below provides the equations for permissible deflection of common snap fit designs:

Table 2 provides allowable strain values for common plastics.

It’s always a good idea to prototype your design with 3-D printing using resins that have similar mechanical properties to what you’re looking to produce. Fictiv and MIT have great design guides regarding snap fits.

In terms of allowable strain and permissible deflection, it’s all about staying within the elastic region of a stress-strain curve as to not induce permanent, plastic deformation.