For mobile phone manufacturing in the 2000’s, phones were made from a wide variety of materials - from generation to generation, it was quite common to see a big change in the housing material!

Traditional Phone Housing Manufacturing:

- Material & Design: Typical phone housings are made using a combination of metal and plastic. The metal frame is usually stamped and then placed into a mold.

- Injection Molding Process: The plastic shell is then injected around this metal frame. This method is efficient and widely used for mass production.

- Cycle Time: The total cycle time per phone can be around 20 seconds. This efficiency allows for the production of large volumes in relatively small industrial spaces.

- Finishing Processes: Additional processes can be added to enhance the appearance and durability of the phone housing, but these usually do not significantly increase the production time.

Predominantly today, mobile phone exteriors are now machined, all-metal housings. The mobile phone housing via one-piece CNC machining solution was first introduced by Apple in the early 2010’s.

Apple’s Approach with Machined Aluminum:

- Material Selection: Apple primarily uses aluminum for its iPhone housings,. This material choice is a significant aspect of their product identity and engineering approach - for almost all other product categories, the primary material used is machined aluminum.

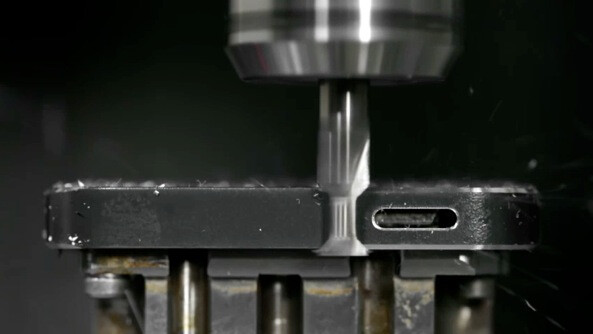

- Machining Process: Unlike the injection molding process, Apple’s iPhones start as a single block of aluminum and undergo a series of machining operations:

- Operations: These include facing, milling, drilling, tapping, and de-burring.

- Machining Tools: They use precision fixtures and a series of mills, with operations increasingly carried out by robots.

- Scale: To meet the demand of 1 million iPhones per day, around 3000 CNC mills are required for just one operation.

- Volume and Equipment: Apple is one of the largest owners of CNC milling machines and Swiss-style lathes, with rumors suggesting around 40,000 machines, half dedicated to iPhone production.

While traditional phone housings are made efficiently through injection molding, most phone housings today are made from CNC machined aluminum frames. To an engineer, it’s counter-intuitive that a labor and cost-intensive process dominates, but this shift reflects a market trend prioritizing durability, precision, and a high-end aesthetic that CNC machining offers, outweighing the cost and labor factors.

The anodized finish of an aluminium part also adds to the aesthetic appeal