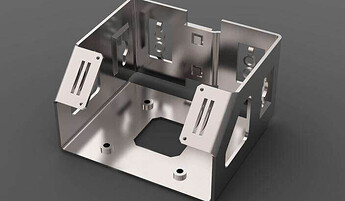

If you take a look at the hardware around, you’ll find that many items, such as the body panels of cars or the chassis of computer servers that host cloud computing like Google Cloud or AWS are products of intricate sheet metal design!

Here are some common guidelines:

- Bend Relief and Radius: Provide sufficient bend relief and appropriate bend radius to prevent material from tearing or deforming. The radius of bends should typically be at least equal to the thickness of the sheet metal.

- Hole Design: Holes should be at least the same distance away from the edge of the material as the thickness of the material, and their diameter should be at least equal to the thickness of the material.

- Avoid Complex Cuts and Shapes: Simplify designs to avoid intricate cuts and complex shapes which are difficult and expensive to bend or cut during the forming operation.

- Consideration for Joining and Assembly: Design parts for ease of assembly and joining, with features like tabs and slots for alignment.

- Corner Design: Avoid sharp corners which can lead to stress concentrations and material failure.

- Tolerances: Apply tolerances that are as generous as possible to make manufacturing easier and reduce costs.

To stiffen a part made from sheet metal, you can use several techniques:

-

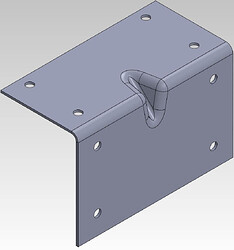

Adding Flanges or Lips: Bending the edges of the sheet metal to form flanges or lips increases the rigidity of the part.

-

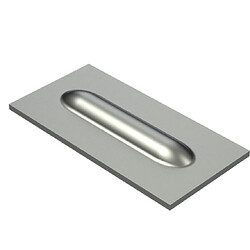

Beads or Embossments: Incorporating beads or embossments into the design adds stiffness without significantly increasing weight.

-

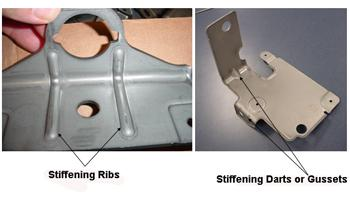

Stiffening Ribbing: Adding ribs to flat surfaces significantly increases the part’s structural integrity and resistance to bending.

-

Gussets: Triangular reinforcements known as gussets can be added at corners or stress points to increase strength.

-

Material Thickness: Increasing the thickness of the material is a straightforward way to increase stiffness, though it also increases weight and material cost.

-

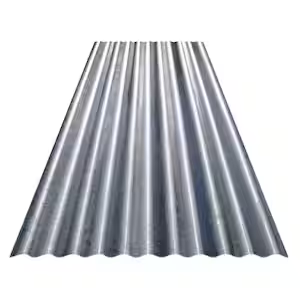

Corrugation: Implementing a corrugated pattern can greatly enhance the stiffness and strength of the part.

-

Cross-breaking: Slight bends or curves across a large flat surface can increase its rigidity.

Each of these techniques has its own implications for the manufacturing process and overall part performance, so they should be chosen based on the specific requirements of the design and its application.