Forced convective cooling is commonly used in consumer electronic devices, where internal components cannot exceed a maximum operating temperature.

If you’re to think of the key dials to select when choosing a fan, they can be best summarized through these criteria:

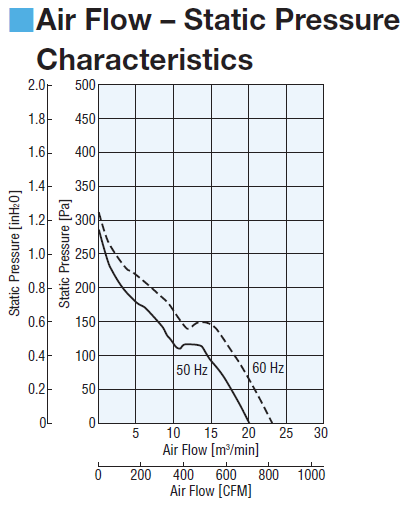

- Airflow: How much air can the fan actually push? Typically listed in cubic feet per minute (CFM) or meters^3/second

- Static Pressure Rating: Think of this as the fan’s ability to overcome resistance to flow. If you have lots of air restriction, fans with higher static pressure ratings can withstand the flow resistance.

- Operating Voltage: Most fans are DC powered at 5V, 12V, or 24V.

- Form Factor: Thickness and length/width dimensions.

- Noise: How many decibels is the fan at max power.

- Efficiency: How much wattage does the fan draw at your rated airflow application?

- Operating Conditions: Different types of fans can push or pull air, and even direct air from one direction to another! One example is with centrifugal blowers in Macbook laptops.

Below is a common example of a CFM vs. Static Pressure graph you’ll find listed in datasheets:

Airflow is typically linked to removing heat from a system, and you’ll typically find this type of work modeled through simulation software using computational fluid dynamics (CFD). Simulation software can allow you to run multiple different trials with alternate fan configurations, moving bodies, and modeling the temperature distribution across key components in the system.